Gear oil pump series

High viscosity pump series

Centrifugal pump series

Pump series for other purposes

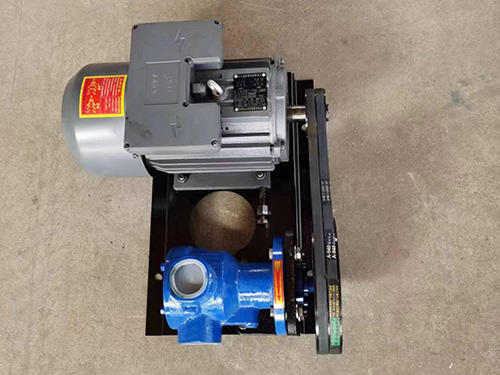

NCB rotor pump

NCB rotary pump is a new type of positive displacement pump developed according to the needs of industries such as petroleum, chemical, coatings, fats, pharmaceuticals, dyes, and food. Due to the selection of different materials and structures, this product is widely used for conveying media with different properties and viscosities.

Applicable medium temperature: -10 ℃ -200 ℃ (the applicable temperature for NYPO.78 and NYP2.3 is -10 ℃ -80 ℃).

Applicable medium viscosity: 1.0cSt -300000cSt (the applicable viscosity for NYPO.78 and NYP2.3 is 1.0cSt -10000cSt).

Advantages of NCB rotor pump

(1) Smooth liquid conveying, no pulsation, low vibration, and low noise.

(2) Some have self suction performance.

(3) The correct selection of component materials can transport various corrosive media, and the operating temperature can reach 200 ℃.

(4) The inner and outer rotors have the same rotation direction, minimal wear, and long service life.

(5) The rotational speed and flow rate of a rotary pump are linearly related, and the flow rate of the pump can be adjusted by changing the rotational speed appropriately.

(6) Especially suitable for conveying high viscosity and viscosity media.

Our conventional NCB rotor pump speed is controlled between 200-500RPM, using stepless speed regulation. However, why is the speed of conventional rotary pumps regulated, and when should we choose no speed regulation or constant speed?

The difference between speed regulation and constant speed:

No speed regulation: Because rotor pumps are usually used for conveying materials, when the customer's material concentration is too high, the speed can be appropriately reduced to prevent motor overload and increase the service life of the motor. Similarly, when the material concentration is relatively low, the rotational speed can be appropriately increased to save time.

Constant speed: Usually, when selecting a rotor pump for customers, if the power is greater than 11KW, we recommend using a constant speed reducer and recommend adding a frequency converter for customers to use. Because after the high-power motor is turned on, it will generate excessive instantaneous current, which will affect the service life of the motor. Therefore, a frequency converter is needed to protect the use of the motor.

Notes:

When adjusting the speed without speed regulation, it is important to wait for the rotor pump to start first before adjusting the gear for speed regulation.

2. Our rotor pumps are all used in conjunction with reducers. If the gear oil inside the reducer decreases, it needs to be added to it.

3. When the material temperature of the customer is below 70 ° C, we usually recommend using a single end mechanical seal for the customer. Therefore, when starting the rotor pump, the customer needs to let the material flow into the pump chamber of the rotor pump before starting the machine. Due to the rotor pump idling, the seal may be damaged and leak due to high temperature. If the temperature is greater than 70 ° C, we will use a double end face sealing structure for the customer. At this time, the customer needs to pass cooling water through the sealing area to cool the sealing components. When the cooling water passes through and there is no material in the pump chamber of the rotor pump, it can also be started.

Performance parameter table of rotor pump:

| model | Entrance and exit caliber | flow | pressure | Inhalation vacuum | speed | machinery | Assembly form | weight | External dimensions | |

| model | power | |||||||||

| NCB-1.2/0.3 | Gi" | 1.2 | 0.3 | 0.03 | 500 | Y90L-6 | 1.1 | W-L | 10 | 234X140X140 |

| NCB-1.8/0.3 | G11/2" | 1.8 | 0.3 | 0.03 | 500 | 1.5 | W-L | 11 | 254X153X153 | |

| NCB-3/0.3 | 3 | 700 | Y100L-6 | 1.5 | W-L | |||||

| NCB-6/0.5 | 40 | 6 | 0.5 | 0.05 | 500 | 3 | W-L | 70 | 700X370X300 | |

| NCB-8/0.5 | 8 | 570 | Y100L2-4 | 3 | W-L | |||||

| NCB-12/0.5 | 50 | 12 | 0.5 | 0.05 | 690 | Y132M1-6 | 4 | W-L | 140 | 800X550X420 |

| NCB-16/0.5 | 16 | 380 | Y132M2-6 | 5.5 | W-L | |||||

| NCB-20/0.5 | 20 | 460 | Y132M-4 | 7.5 | W-L | |||||

| NCB-12/0.7 | 80 | 12 | 0.7 | 0.05 | 220 | Y160M-6 | 7.5 | W-L | 330 | 910X780X500 |

| NCB-18/0.7 | 18 | 310 | Y160L-6 | 11 | W-L | |||||

| NCB-24/0.5 | 24 | 0.5 | 0.05 | 420 | Y10M-4 | 11 | W-L | |||

| NCB-30/0.5 | 30 | 520 | Y160L-4 | 15 | W-L | |||||

| NCB-40/0.5 | 12 | 40 | 0.5 | 0.06 | 230 | Y200L1-6 | 18.5 | W-L | 750 | 1240X1022X610 |

| NCB-50/0.5 | 50 | 290 | Y200L2-6 | 22 | W-L | |||||

| NCB-60/0.5 | 60 | 350 | Y200L2-6 | 22 | W-L | |||||

| NCB-70/0.5 | 70 | 410 | Y225M-6 | 30 | W-L | |||||

| NCB-80/0.5 | 80 | 470 | Y200L-4 | 30 | W-L | |||||

| NCB-100/0.5 | 150 | 100 | 0.5 | 0.06 | 320 | Y280S-6 | 45 | W-L | ||

| NCB-120/0.5 | 120 | 380 | Y280M-6 | 55 | W-L | |||||

| NCB-150/0.5 | 150 | 480 | Y280S-4 | 75 | W-L | |||||

Why Gear Oil Pumps Cannot Be Used for Water Pumping

Why can gear oil pumps not be used for pumping water? This question touches on the fundamen ...

2026-02-02

How to choose a gear pump when transporting media that solidifies at room temperature

When transporting media that solidifies at room temperature, specialized insulated gear pum ...

2026-01-28

How to prevent gear pumps from clogging when pumping adhesive

The core to prevent clogging when using a gear pump to draw glue lies in strict operating p ...

2026-01-19

Guidelines for Daily Maintenance and Troubleshooting of Gear Pumps

The maintenance of gear pumps focuses on regular inspections, timely servicing, and operati ...

2025-12-24