Gear oil pump series

High viscosity pump series

Centrifugal pump series

Pump series for other purposes

NCB stainless steel pump

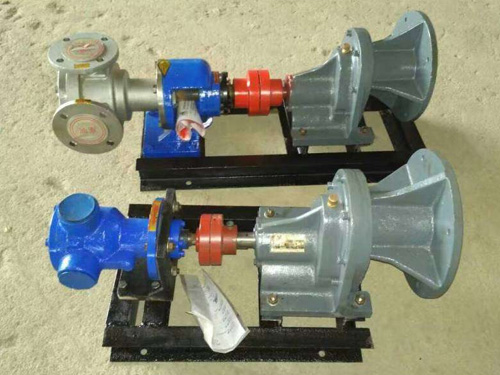

Main components and components of NCB stainless steel pump

NCB stainless steel pump cover, small shaft, small shaft sleeve, small gear, internal gear, pump body, main shaft, main shaft sleeve, packing seal or mechanical seal, packing gland or sealing gland, pump seat, front bearing cover, bearing, rear bearing cover.

NCB Stainless Steel Pump Materials and Service Media

1) Cast iron material - suitable for conveying high viscosity fluid media without solid metal particles, mostly used in industrial conditions, such as coal tar, crude oil, lithium grease, etc.

2) Stainless steel material - suitable for conveying high viscosity fluid media without solid metal particles, mostly used in the chemical and food industries, such as acid and alkaline chemical fluid media, toothpaste, honey and other food media.

Working characteristics of NCB stainless steel pump

1) The NCB stainless steel gear pump adopts internal meshing rotor gears, so the inner and outer rotors operate in the same direction during gear operation, with almost zero wear on the tooth profile. When conveying media with high cleanliness and lubrication, the service life of the rotor pump increases significantly compared to that of ordinary gear pumps. And it has significant characteristics of no pulsation and superior noise reduction performance.

2) NCB stainless steel gear pump can transport high viscosity media with viscosity ranging from 1.0 cSt to 300000 cSt, with stable pulsation, no noise, and long service life. If the viscosity of the conveying medium is high, it is recommended to choose a reducer to achieve optimal conveying efficiency.

The NCB stainless steel pump stainless steel series is divided into:

Stainless steel 304

Stainless steel 316

Stainless steel 316L

Applied to transport various media with different properties, such as oil industry, chemical industry, industry, and product industry.

Technical parameters:

| model | Entrance and exit caliber | flow | pressure | Inhalation vacuum | speed | electrical machinery | Assembly form | weight | External dimensions | |

| model | efficiency | |||||||||

| NCB-1.2/0.3 | Gi" | 1.2 | 0.3 | 0.03 | 500 | Y90L-6 | 1.1 | W-L | 10 | 234X140X140 |

| NCB-1.8/0.3 | G11/2" | 1.8 | 0.3 | 0.03 | 500 | 1.5 | W-L | 11 | 254X153X153 | |

| NCB-3/0.3 | 3 | 700 | Y100L-6 | 1.5 | W-L | |||||

| NCB-6/0.5 | 40 | 6 | 0.5 | 0.05 | 500 | 3 | W-L | 70 | 700X370X300 | |

| NCB-8/0.5 | 8 | 570 | Y100L2-4 | 3 | W-L | |||||

| NCB-12/0.5 | 50 | 12 | 0.5 | 0.05 | 690 | Y132M1-6 | 4 | W-L | 140 | 800X550X420 |

| NCB-16/0.5 | 16 | 380 | Y132M2-6 | 5.5 | W-L | |||||

| NCB-20/0.5 | 20 | 460 | Y132M-4 | 7.5 | W-L | |||||

| NCB-12/0.7 | 80 | 12 | 0.7 | 0.05 | 220 | Y160M-6 | 7.5 | W-L | 330 | 910X780X500 |

| NCB-18/0.7 | 18 | 310 | Y160L-6 | 11 | W-L | |||||

| NCB-24/0.5 | 24 | 0.5 | 0.05 | 420 | Y10M-4 | 11 | W-L | |||

| NCB-30/0.5 | 30 | 520 | Y160L-4 | 15 | W-L | |||||

| NCB-40/0.5 | 12 | 40 | 0.5 | 0.06 | 230 | Y200L1-6 | 18.5 | W-L | 750 | 1240X1022X610 |

| NCB-50/0.5 | 50 | 290 | Y200L2-6 | 22 | W-L | |||||

| NCB-60/0.5 | 60 | 350 | Y200L2-6 | 22 | W-L | |||||

| NCB-70/0.5 | 70 | 410 | Y225M-6 | 30 | W-L | |||||

| NCB-80/0.5 | 80 | 470 | Y200L-4 | 30 | W-L | |||||

| NCB-100/0.5 | 150 | 100 | 0.5 | 0.06 | 320 | Y280S-6 | 45 | W-L | ||

| NCB-120/0.5 | 120 | 380 | Y280M-6 | 55 | W-L | |||||

| NCB-150/0.5 | 150 | 480 | Y280S-4 | 75 | W-L | |||||

Reasons and Solutions for Gear Pump Not Feeding

The reasons for gear pumps failing to draw material (also known as suction failure or cavit ...

2026-02-09

Why Gear Oil Pumps Cannot Be Used for Water Pumping

Why can gear oil pumps not be used for pumping water? This question touches on the fundamen ...

2026-02-02

How to choose a gear pump when transporting media that solidifies at room temperature

When transporting media that solidifies at room temperature, specialized insulated gear pum ...

2026-01-28

How to prevent gear pumps from clogging when pumping adhesive

The core to prevent clogging when using a gear pump to draw glue lies in strict operating p ...

2026-01-19